Introduction

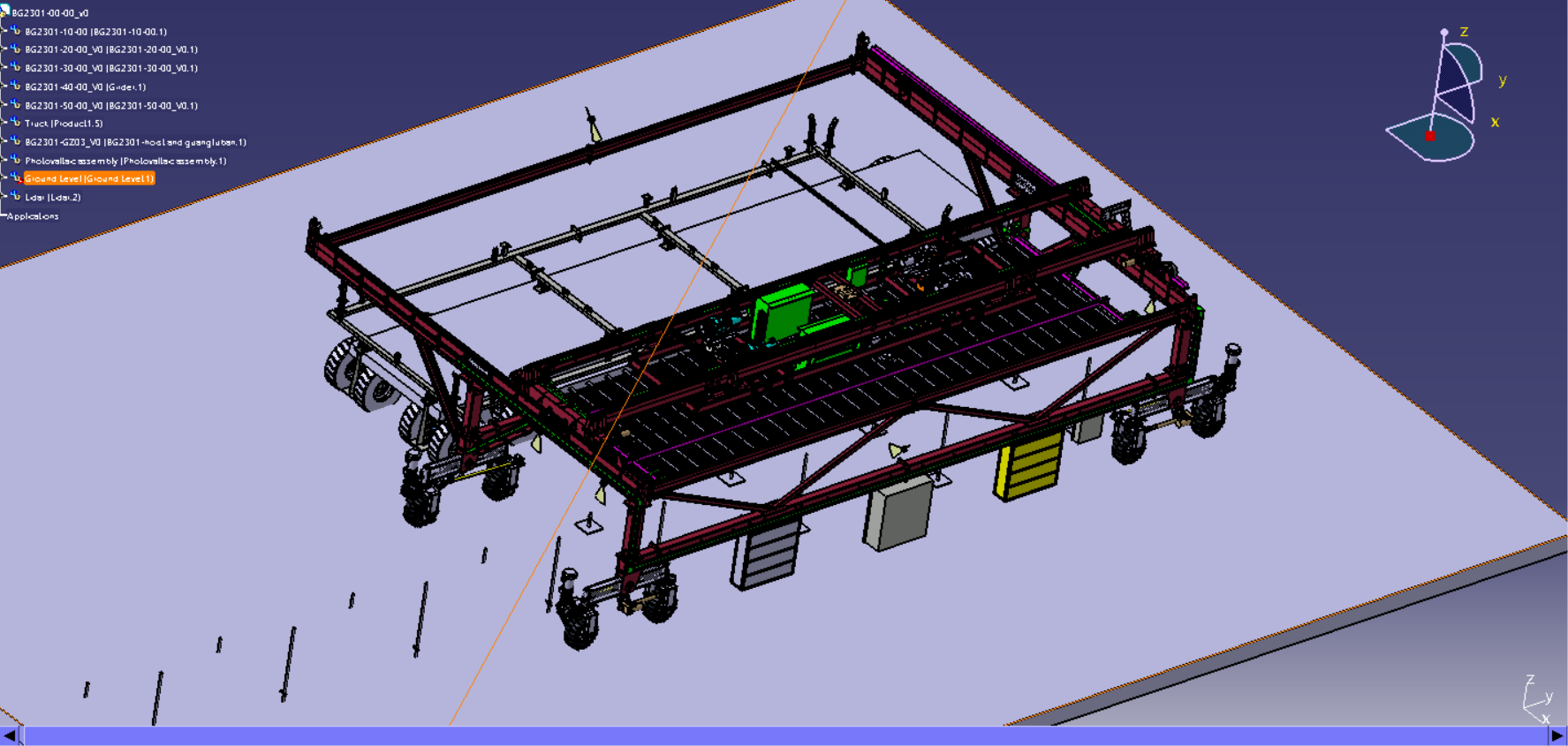

Our project is part of a big Industrial project – Bolight Industrial Robot, shown in Figure 1. The overall purpose of the industrial project is to transport large solar panels in the desert with a large wheeled mobile lifting robot of Ackerman structure. If collects sensor data such as LiDAR and dGPS to recognize the environment state and then plan to place the solar board to the corresponding position. Our project mainly concentrate on the upper structure of the robot, which a lifting device driven by "4-ropes", which could consider it as a 4-Cable-Driven Parallel Robots (CDPR).

Our project is a sub-module of the overall industrial project with the following targets:

- Export and improve URDF files from the original CAD file for simulation.

- Simplify the CDPR model into a compact structure with revolute joint and Prismatic joint and then compute the kinematic and inverse kinematic transformations from the original "rope" to the "virtual bar" model.

- Use ROS packages including MoveIt to control our own model.

- Implement the interface and simulation of the real robot.

System Description

At the beginning, we will extract the main structure as STL files from the CAD files provided by the industrial company and then finish the XACRO files describing the simplified compact structure. As it's hard to describe the CDPR mechanism structure in URDF format, We need to model it as a virtual revolute and prismatic joint. We also need forward and inverse kinemtatic for that, which means given cable lengths, calculating prismatic and revolute joint values and given prismatic and revolute joint values, calculating cable length. Since we don't know whether our simplification will lose some accuracy of the original CDPR model. We need to take this step carefully and refer to some literature related to CDPR. Then We will also use MoveIt! to manipulate this robot model, doing kinematic and inverse kinematic computations, motion planning and manipulation. Our project consists of 3 ros packages: megatron_description, megatron_publisher_simulator and megatron_arm_interface.

Experiment

In this section, we describe the experimental implementation of our system, which involved the integration of a visual demo in Rviz and testing on a real industrial robot. Our goal was to establish bidirectional communication between Rviz and the robot, enabling control over the robot's joints.

Implementation of Visual Demo in Rviz We successfully developed a visual demo in Rviz, leveraging its 3D visualization capabilities. The demo served as an interface for controlling the 4-rope robot's movements. We utilized Rviz's interactive markers and GUI features to ensure user-friendly interaction.

Testing on a Real Industrial Robot We conducted tests on a large industrial robot to evaluate the performance of our system in a real-world scenario. This allowed us to validate the bidirectional communication between Rviz and the physical robot.

Receiving Messages from the Real Robot to Control Rviz Demo A significant achievement was establishing a communication channel that enabled the real robot to send messages to control the Rviz demo. This allowed us to synchronize the robot's movements with the visual representation in Rviz.

Sending Messages to Control Robot Joints Furthermore, our system demonstrated the capability to send messages from Rviz to control the individual joints of the real industrial robot. This bidirectional control facilitated seamless coordination between the Rviz demo and the physical robot's movements.

Conclusions

Our project will finish XACRO files refer to given CAD files and then control and simulate it within ROS using packages including MoveIt. This would work as a sub-part of a real working industrial robot within ROS, transporting the solar racks to correct position and pose in the desert. Our work could work as the basic components for further meaningful tasks. Additionally, since the pose determination of the CDPR model is a difficult task due to the elasticity and changing shape of the ropes and it's also hard to simulate in most of the tools, we hope that the technique we used to simplify the model and computing the kinematic and inverse kinematic model could give an easy to approximately simulate CDPR models with acceptable accuracy.

Our experiments confirmed the successful implementation of the visual demo in Rviz and its integration with a real industrial robot. The bidirectional communication between Rviz and the robot allowed for effective control over the robot's joints, showing the practical applicability of our system.