A project of the Robotics 2017 class of the School of Information Science and Technology (SIST) of ShanghaiTech University.

Course Instructor: Prof. Sören Schwertfeger; Project Advisor: Prof. Andre Rosendo

Yang Dan and Hu Hang

Introduction

There are three stages we implemented in this project.

At the first stage, we make the Dobot Arm automatically print, grab and seal. An ordinary 3D printed product has all its parts connected to each other, so our goal is to print some small objects inside a container with every part separated to each other. To do this, we integrate a gripper into the 3D printing system of Dobot Arm.

As for the second stage, we print a Matryoshka doll and put them together using the gripper. The main difference between this stage and the previous stage is that grabbing a lid onto the other object will need a much more accurate control of the gripper than simply placing one object into the other.

At the third stage, we try to achieve real 3D printing and are able to print objects like pyramids and cubes. Existing 3D printers are actually "2.5D" , since they print objects layer by layer. What we want do is to print objects in the real 3D way.

The major task is to figure out how to control the gripper with 3D Printing framework first. Then do experiments with the material under different conditions to find the best setting for printing so that we can achieve real 3D printing.

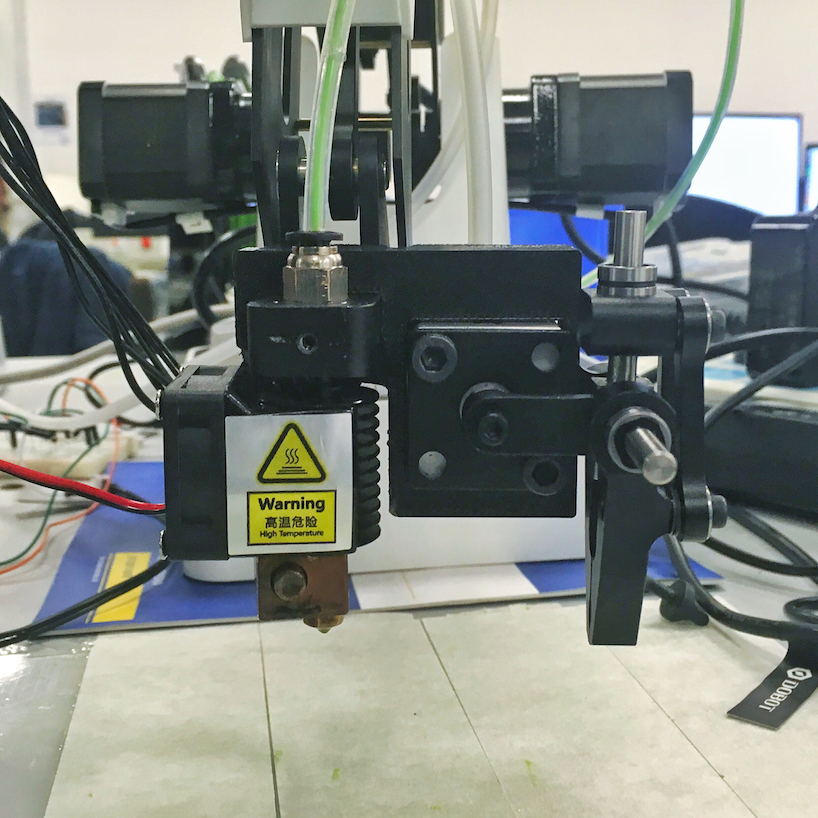

The hardware we used is a 4-Degree-of-Freedom (DOF) Dobot Magician arm, with high accuracy and multi function including grabbing, 3D printing and laser printing, etc. However, only one function can be applied at one time due to the limitation of the framework.

In this report, we first present some related papers and softwares in the State-Of-Art part, and then describe our system in the Project Description part. The results will be shown in the System Evaluation part and the conclusion comes at last.

System Description

Hardware

To control the 3D printer and the gripper at the same time, a 3D printed object is designed to connect them.

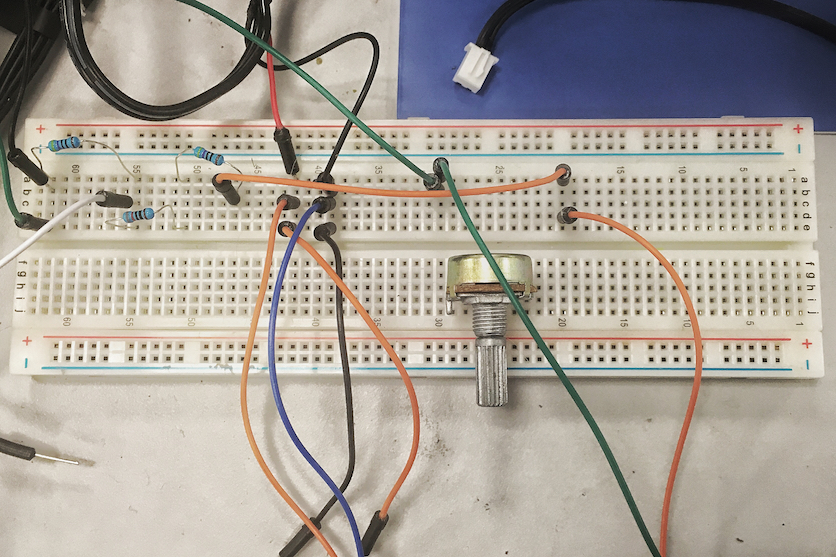

The fan and the pump is powered by directly by the power supply, and the port that used to control the fan is used to control the gripper in our system. We build a voltage divider to divide the 12V voltage from the port into 3V signal that the pump need.

Software

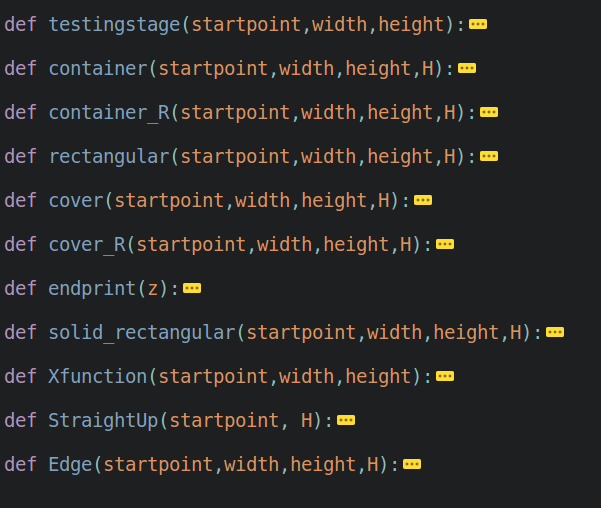

We write a python program to accomplish 3D printing and grabbing, and here is some of the functions that used to implement our slicer.

Demos

Demo 1:

Basic functions: 3D printing and grabbing at the same time.

Demo 2:

Matryoshka Doll

Demo 3:

Real 3D printing